From sewage sludge to green gas and green cement

There is a lot happening in the world of water management. And who knows, the future may look very different if the Alkmaar-based company SCW lives up to expectations. Namely, a lot greener and more circular.

SCW (Super Critical Water), based in Boekelermeer, Alkmaar, will start producing green circular gas from raw glycerol and other sources on an industrial scale this summer. This residual product from the biodiesel industry is supercritically gasified under high pressure and temperature. This is the first supercritical gasification plant in the world! After glycerol, the intention is to start gasifying plastic and sewage sludge. An extensive research programme is currently underway programme produce circular gas from plastic, which can then be used as a raw material for new plastic materials. In addition, the water boards affiliated with the HVC are planning to start a similar programme sewage sludge, including sludge from the Hollands Noorderkwartier Water Board.

From centuries to seconds

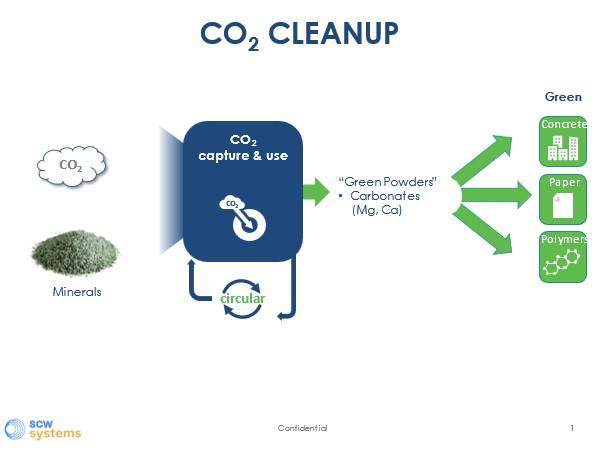

In addition to this gasification technology, SCW has developed a second revolutionary technology to directly bind CO2 contained in the produced gas (=syngas) to ground rock (minerals) that is widely available worldwide. SCW has managed to reduce this natural process, which normally takes centuries, to seconds. They call this processCO2 CLEAN UP. During this process, powders are created to which the CO2 is bound, and these powders serve as the basis for useful products. A good example is the direct application of one of these powders for making cement.

Green cement

This powder can be used as the main component in this new cement. In fact, you could call it "green cement" that can be used to make CO2-negative concrete: concrete in which CO2 is permanently stored. The conventional method of making cement is extremely energy-intensive and responsible for 5-9% of global CO2 emissions! SCW'sCO2 CLEAN UP process permanently captures CO2 in useful products, thereby preventing the manufacture of products that release large amounts of CO2. Think, for example, of cement and concrete. This makes the entire process CO2 negative, which actually reduces the CO2 concentration in the air, hence the nameCO2 CLEAN UP.

Circular business operations

The water authorities are keen to be the first to use this cement. This will enable them not only to contribute to reducing CO2 in the atmosphere, but also to take the next step towards circular business operations.

acknowledgement green

Water authorities also produce a lot of CO2 in biogas and, with this technology, would also be able to achieve negative emissions on a large scale and are joining forces with SCW. But two things are important. CO2 from biogas and syngas must be recognized as green; only by capturing green CO2 extracted from the atmosphere can you achieve negative emissions. In addition, SCW's technology must be recognized as an official carbon recovery and storage technology, as well as a circular application technology if it is used to produce green cement. The water authorities have entered into discussions with the Rijksoverheid about this, together with SCW.

Clean Up factory

Meanwhile, work on the Boekelermeer continues as usual. SCW plans to have a CO2 mineralization plant operational in the first half of 2023 that can permanently store 15 Kton of CO2 annually. This will be located on the North Holland Canal. If expectations are met, HHNK will be able to start using the first green cement products in 2023, with CO2 recovered from its own biogas, directly from the atmosphere, and eventually even from its own sewage sludge.